The model of this product is RAV-4 06-,The oe number of the product is:45503-0R030,45047-09335,45046-09675.oeproduct namecar model45503-0R030Inner Ball Joint L/RRAV-4 06-45047-09335Outer Ball Joint LRAV-4 06-45046-09675Outer Ball Joint RRAV-4 06-Jinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

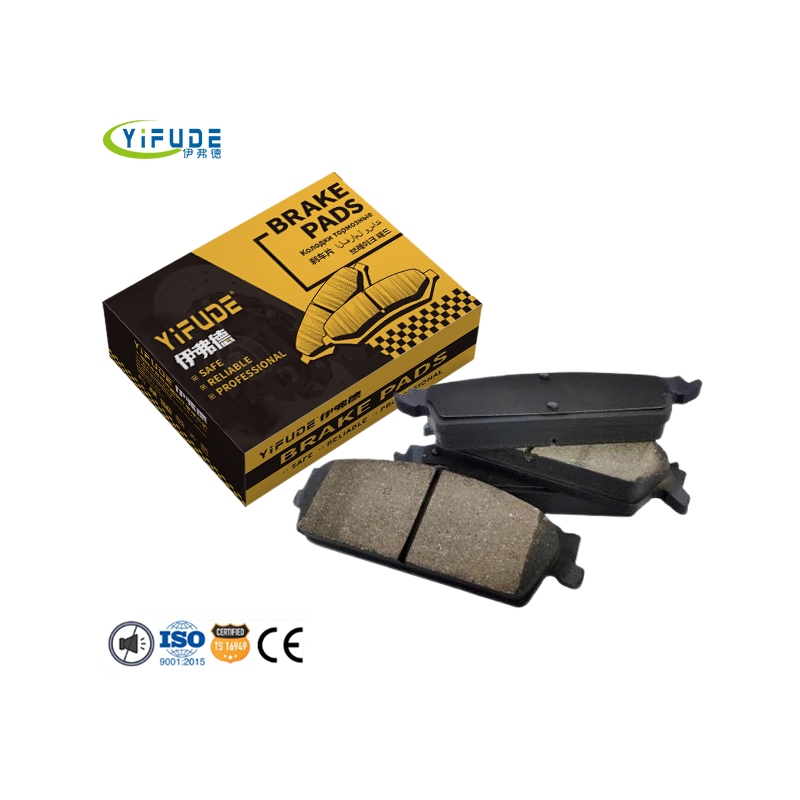

Premium Quality Built to stringent OE specifications and strict quality control standards by the professional OEM manufacturer, 100% function tested for reliable performanceBetter Performance Corrosion-resistant coating for long-life performance, greased ball joints for easy maintenance, light-weight construction for application requirements, meet or exceed OE form, fit and functionPerfect Fit Direct replacement for a proper fit, brand new control arms with ball joints are pre-assembled for a trouble-free installationAmazing Price Factory direct pricing with no middleman markup delivers except

Contact Now

Buyer Notice - Please check the original equipment part numbers and the application for the replacement, buy the right one you needNo.GradeCar BrandCar ModelProduct NameExisting Assmbly CodeNew CodeQuantity /cartonYearOutput617CImported Audi Audi Q7 (4LB) Front Left Shock Absorber (With Buffer Spring)Audi Q7 (4LB) Front Left Shock Absorber (With Buffer Spring)946030462006.03-2015.083.0T,3.6L,4.2L,6.0L618CImported Audi Audi Q7 (4LB) Front Right Shock Absorber (With Buffer Spring)Audi Q7 (4LB) Front Right Shock Absorber (With Buffer Spring)9460303620

Contact Now

"Premium Quality Built to stringent OE specifications and strict quality control standards by the professional OEM manufacturer, 100% function tested for reliable performanceBetter Performance Corrosion-resistant coating for long-life performance, greased ball joints for easy maintenance, light-weight construction for application requirements, meet or exceed OE form, fit and functionPerfect Fit Direct replacement for a proper fit, brand new control arms with ball joints are pre-assembled for a trouble-free installationAmazing Price Factory direct pricing with no middleman markup delivers

Contact Now

About this item【Premium Quality】Built to stringent OE specifications and strict quality control standards by the professional OEM manufacturer, 100% function tested for reliable performance【Better Performance】Corrosion-resistant coating for long-life performance, greased ball joints for easy maintenance, light-weight construction for application requirements, meet or exceed OE form, fit and function【Perfect Fit】Direct replacement for a proper fit, brand new control arms with ball joints are pre-assembled for a trouble-free installation【Amazing Price】Factory direct pricing with no middleman mar

Contact Now

About this item【Premium Quality】Built to stringent OE specs and strict great manage requirements via the expert OEM manufacturer, one hundred percent feature examined for dependable performance【Better Performance】Corrosion-resistant coating for long-life performance, greased ball joints for effortless maintenance, lightweight building for software requirements, meet or exceed OE form, in shape and function【Perfect Fit】Direct alternative for a perfect fit,&

Contact Now

This ball joint is suitable for Honda CR-V 07-11 RE.oeproduct name car model53010-SWC-G01Inner Ball Joint L/RCR-V 07-11 RE53010-SWA-000Inner Ball Joint L/R (2.4)CR-V 07-11 RE51220-SWN-H01Suspension Ball Joint L/RCR-V 07-11 RE53540-SWA-A01Outer Ball Joint L/RCR-V 07-11 REJinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

oeProduct nameModel20817752Inner Ball JointL/RBuick Enclave 09-20905104Front Stabilizer Rod L/RBuick Enclave 09-15869897Outer Ball Joint L/RBuick Enclave 09-Jinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

Prado 3400 96-RZJ95 Ball Joint is a component suitable for Japanese Honda brand cars. Its main function is to connect the steering system and suspension system of the vehicle to ensure the stability and handling of the vehicle when driving. It uses high-quality materials and precise manufacturing processes to ensure the durability and reliability of the product. In addition, Prado 3400 96-RZJ95 Ball Joint also has good versatility and compatibility, which can be applied to most Japanese Honda brand cars.

Contact Now

The Prado 4000 03- GRJ12 Ball Joint is a component in the Toyota Prado 4000 model that connects the ball head and frame in the suspension system. Its main role is to ensure the stability and comfort of the vehicle, while also reducing vibration and noise.This ball head is made of high-strength steel with good durability and corrosion resistance. Its ball part is made of high-quality wear-resistant materials, which can maintain stable steering ability at high speeds and harsh road conditions.

Contact Now

Ford Mondeo 07 ball joint is a replacement part that connects the steering knuckle to the lower control arm of a car. The ball joint is a critical component of the suspension system, as it allows the wheel to rotate and make steering movements. The ball joint on the Ford Mondeo 07 is designed to withstand the forces and stresses of everyday driving, including steering and cornering.The ball joint is made from high-quality materials and features a ball-and-socket design that allows for a wide range of movement.

Contact Now

The Ford Focus 12 Ball Joint is a part that connects the wheel assembly to the suspension system. It is responsible for allowing the wheel to rotate freely while maintaining its position relative to the vehicle's frame.The ball joint is typically made of a rubber-coated steel component that is connected to the suspension arm by a pivot point. The ball joint's ball socket is located at the top of the socket and is made of a high-quality steel that is resistant to wear and tear.

Contact Now

This is for Prado 09- GRJ150 Outer Inner Ball Joint model, the oe number of this Prado 09- GRJ150 is: 32106871884 32106871892 RBMW002 BBMW024L BBMW024R.Jinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

Jinan YIFUDE Electromechanical Equipment Co., Ltd. is located in the beautiful capital city of Shandong Province - Jinan - the City of Spring. YIFUDE founded in 2006, and the company successfully passedd the trademark registration of "YIFUDE" at the same year. After years of hardwork, YIFUDE has gradually developed into a new comprehensive modern enterprise integrating design, research and development, manufacturing and sales & services. JJinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

Reliable Alternative: With its precise design, this control arm and ball joint assembly serves as a trustworthy substitute, providing a direct replacement for the original assembly in specific vehicle applications.Comprehensive Restoration: Simplify the repair process with this assembly that includes pre-installed ball joints and bushings, eliminating the need for multiple installations.Exceptional Engineering: Through rigorous industry testing, this assembly has been proven to deliver a smooth, safe, and stable ride, reflecting its superior quality.Enhanced Strength: The incorporation of extr

Contact Now

MOOG's advanced control arms for major domestic and foreign automobile brands have been engineered to have structural strength and corrosion resistance.Carbon Fiber Bearings - Induction hardened bolts for added strength, combined with patent pending carbon fiber reinforced bearings, reduce sleeve friction and extend sleeve life compared to typical unreinforced bearings.High Precision Engineering - Optimized design for quiet operation and helps resist wear, salt, road grime and oil.Plug and play - pre-installed ball joints and sealing sleeves, can be used without maintenance.LONG LIFE - The

Contact Now

Unparalleled Excellence: Crafted by a professional OEM to adhere to strict OEM specifications and pass rigorous quality control standards, these control arms are guaranteed to deliver outstanding quality and reliable performance.Optimal Performance: Featuring a corrosion-resistant coating for extended lifespan and greased ball joints for effortless maintenance, these control arms offer superior functionality.Effortless Installation: With their simple and lightweight design, these control arms are tailored to meet diverse application needs while maintaining OE form, fit, and function.

Contact Now

Unparalleled Quality: Crafted by a skilled OEM according to stringent OEM specifications and rigorous quality control standards, each component undergoes 100% testing to ensure dependable performance. Unrivaled Performance: Boasting a corrosion-resistant coating for extended longevity and greased ball joints for hassle-free maintenance, these control arms offer superior functionality. Effortless Installation: With a simple and lightweight design tailored to fit diverse application needs, our new ball joint control arms come preinstalled for convenient and problem-free installation.&n

Contact Now

Increased structural strength. The robust construction withstands repeated shock loads, making it more stable in operation. Premium Ball Joints For quiet operation, agility and durability, we selected premium ball joints for our tubular upper control arms.

Contact Now

Optimizing Suspension Response: How Control Arm Design Enhances Ride Comfort""Enhancing Handling Performance: The Impact of Control Arm Design on Vehicle Dynamics"The coping with overall performance of a car is noticeably influenced with the aid of the diagram and adjustment of its manipulate arm. The manage arm performs a critical position in supplying secure suspension guide and decreasing physique tilt and roll.

Contact Now

About this itemDurably designed - extra coatings provide long-lasting rust and corrosion resistance,product has vivid and stunning color, prevents growing older and falling off, and ensures safety.The ball joint is uniform and full, the substances are sufficient, thick, and stop deformation and fracture.Use extraordinary add-ons to make certain the excessive nice of the products.Our manipulate palms have huge applicability,meets the wishes of most&nbs

Contact Now

About this item· Trustworthy replacement - this control arm and ball joint assembly directly replaces the original assembly on specific vehicle applications· Complete repair - each assembly includes pre-installed ball joint and bushings, saving time and labor· Quality engineering - underwent industry-leading testing to ensure a smooth, stable and safe ride,we have 100% quality test before delivery.· Durably designed - additional coatings offer long-lasting rust and corrosion resistance,product has bright and beautiful color, prevents aging and falling off, and ensures safet

Contact Now

Direct Substitution: Designed to be a dependable substitute, this control arm and ball joint assembly directly replaces the original assembly found in specific vehicle applications.Complete Restoration: Each assembly is supplied with pre-installed ball joints and bushings, eliminating the need for separate installations and streamlining the repair process.Top-Quality Engineering: Rigorously tested in the industry, this assembly is engineered to deliver a smooth, safe, and secure ride, prioritizing performance and longevity.Long-Lasting Durability: Enhanced with additional coatings, this assemb

Contact Now

MOOG advanced control arms designed for foreign and domestic brands have structural strength and corrosion resistance.Carbon Fiber Bearings - Induction hardened studs for increased strength, combined with patent pending carbon fiber reinforced bearings, compared with non-reinforced bearings, reduces sleeve friction and prolongs sleeve life.High Precision Engineering - Optimized design ensures quiet operation and helps protect against wear, salt, road grime and oil.Ready to install - pre-assembled ball joint and sealing sleeve, no maintenance.Long Life - The ball pin shape guarantees fatigue li

Contact Now