Long-lasting durabilityEnhanced stopping powerLow noise and vibrationImproved handling and stabilityEnergy-efficient and eco-friendlyPerfectly compatible with various brake systemsCost-effective replacement solutionPremium quality and consistent performanceIndustry-leading manufacturer reliability and reputationExceptional value for money.1. What products do you have ? Main products are brake pads , brake backing plate, brake repair kits , brake wear sensor, brake shoes, brake discs.2. What is the MOQ ?Truck Brake pads MOQ is 50 sets/item, 500 sets/order .3.

Contact Now

Apply to ACURA CL 4 Cylinder 1997-1999 HONDA Accord Coupe 1998-1999 HONDA Accord Coupe V6 2002 HONDA Accord Sedan 1998-2002 HONDA Civic 2006-2011 HONDA Civic EX 2006-2011 HONDA Civic GX 2001 HONDA Civic Si 1999-2000 HONDA Civic Si 2002-2003 HONDA Insight 2010-2014.Standard Export Package: Plastic Bag Shrink + Neutral / Brand box + Carton Box + Pallet.The size of the product:Front width1:137.5 height1:52.2 Thickness:15.9

Contact Now

The Ford Escort ball joint is a vital component in the suspension system of your vehicle. It serves as the connecting point between the steering knuckle and the control arm, allowing for smooth and accurate steering. The ball joint is responsible for transferring the power from the steering rack to the control arm, and as such, it must be strong and reliable.At its core, the Ford Escort ball joint is a ball-and-socket joint, which is made up of a spherical ball at the end of the control arm and a socket-shaped opening in the steering knuckle.

Contact Now

This ball joint is suitable for NISSAN Patrol Y62 ball joint.OEproduct namecar modelD8521-1LB0AInner Ball Joint L/RPatrol Y62D8640-1LB0AOuter Ball Joint LPatrol Y62D8520-1LB0AOuter Ball Joint RPatrol Y62Jinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

Prado 3400 96-RZJ95 Ball Joint is a component suitable for Japanese Honda brand cars. Its main function is to connect the steering system and suspension system of the vehicle to ensure the stability and handling of the vehicle when driving. It uses high-quality materials and precise manufacturing processes to ensure the durability and reliability of the product. In addition, Prado 3400 96-RZJ95 Ball Joint also has good versatility and compatibility, which can be applied to most Japanese Honda brand cars.

Contact Now

This is for BMW X3 G08 18- Outer Inner Ball Joint model, the oe number of this BMW X3 G08 18- is: 32106871884 32106871892 RBMW002 BBMW024L BBMW024RJinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

"Premium Quality Built to stringent OE specifications and strict quality control standards by the professional OEM manufacturer, 100% function tested for reliable performanceBetter Performance Corrosion-resistant coating for long-life performance, greased ball joints for easy maintenance, light-weight construction for application requirements, meet or exceed OE form, fit and functionPerfect Fit Direct replacement for a proper fit, brand new control arms with ball joints are pre-assembled for a trouble-free installationAmazing Price Factory direct pricing with no middleman markup delivers

Contact Now

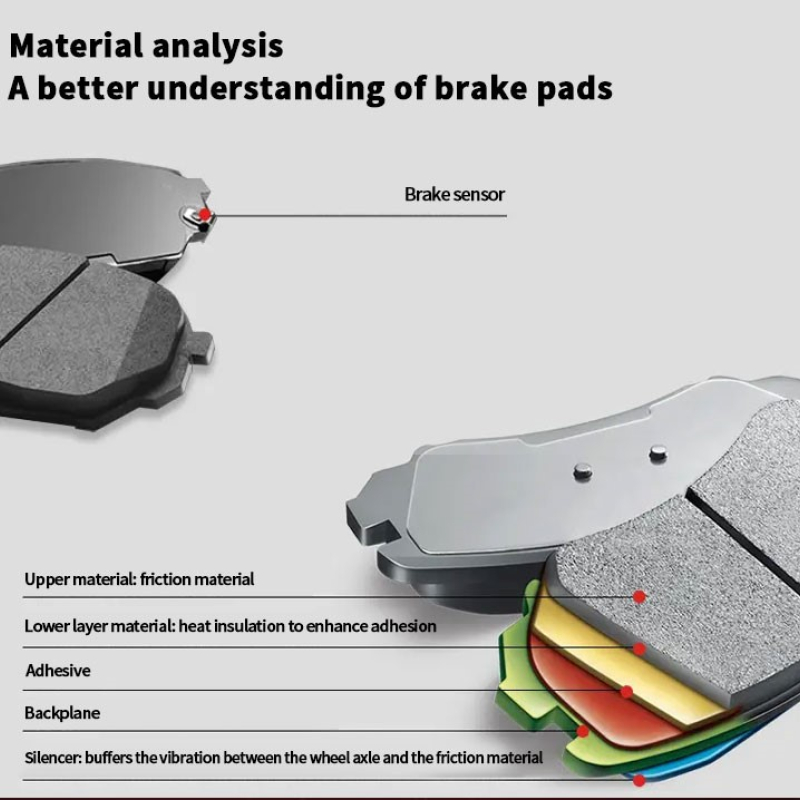

Disc Brake PadLet's face it, brakes pads hands down are the most important components of our vehicle. Our brake pads allow us to stop our vehicles with a simple push of a brake pedal. Unfortunately they don't last forever and are considered to be a major wear item which must be replaced before they completely wear out and damage the brake rotor costing you more in repairs. Brake pads can be made of several materials such as a semi-metallic compound, ceramic compound, or organic.

Contact Now

two kinds SEMI-METALLIC brake pads Formular code:YIFUDE110 Friction level:EE Life(KMS):40,000-70,000 Advantage: High quality semi-metallic ,contains 60% metal fiber,longest life in all semi-metallic ,suir for heavy truck or Van.

Contact Now

MOOG advanced control arms designed for foreign and domestic brands have structural strength and corrosion resistance.Carbon Fiber Bearings - Induction hardened studs for increased strength, combined with patent pending carbon fiber reinforced bearings, compared with non-reinforced bearings, reduces sleeve friction and prolongs sleeve life.High Precision Engineering - Optimized design ensures quiet operation and helps protect against wear, salt, road grime and oil.Ready to install - pre-assembled ball joint and sealing sleeve, no maintenance.Long Life - The ball pin shape guarantees fatigue li

Contact Now

Disc Brake PadLet's face it, brakes pads palms down are the most necessary elements of our vehicle. Our brake pads enable us to quit our automobiles with a easy push of a brake pedal. Essentially brake pads convert the kinetic strength of the automobile to thermal electricity via friction.

Contact Now

Superior stopping power: Our brake pads are engineered to provide consistent and reliable braking performance, even under extreme conditions.Long-lasting durability: Our brake pads are made from high-quality materials that are designed to last longer than traditional brake pads, reducing the need for costly brake replacements.Reduced brake dust: Our brake pads are designed to reduce brake dust, helping to maintain a clean and healthy driving environment.Easy installation: Our brake pads are easy to install and can be done in most cases without professional assistance.Competitive pricing: Our b

Contact Now

Our commercial enterprise way is spot sales, if the gadgets we have stock, there is no drawback for MOQ, and usually MOQ as four pcs is(1).We have a lot of stock in stock, you simply want to supply the oe number, we have been doing auto components on the grounds that 2006.(2.)We have a one-year great guarantee, and we can additionally customise product packaging for you。

Contact Now

Jinan YIFUDE Electromechanical Equipment Co., Ltd. is located in the beautiful capital city of Shandong Province - Jinan - the City of Spring. YIFUDE founded in 2006, and the company successfully passedd the trademark registration of "YIFUDE" at the same year. After years of hardwork, YIFUDE has gradually developed into a new comprehensive modern enterprise integrating design, research and development, manufacturing and sales & services. JJinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

This break pads Apply to ALFA ROMEO 164 1990-1995AUDI 100 1992-1994AUDI 100 Quattro 1989AUDI 200 1989AUDI 200 Quattro 1989AUDI 4000 Quattro 1985-1987AUDI 5000 Quattro 1986-1988AUDI 80 Quattro 1988-1989AUDI 90 1994-1995AUDI 90 Quattro 1988-1989AUDI 90 Quattro 1994-1995AUDI A4 1996AUDI A4 1998-1999AUDI A4 Quattro 1999-2002AUDI A4 Quattro Avant 1998 AUDI A6 1995-1997AUDI A6 Quattro 1996-1997 AUDI A8 1997-1999AUDI A8 Quattro 1997-2000AUDI Cabriolet 1994-1998 AUDI Coupe Quattro 1990 AUDI Quattro 1985

Contact Now

MOOG's advanced control arms for major domestic and foreign automobile brands have been engineered to have structural strength and corrosion resistance.Carbon Fiber Bearings - Induction hardened bolts for added strength, combined with patent pending carbon fiber reinforced bearings, reduce sleeve friction and extend sleeve life compared to typical unreinforced bearings.High Precision Engineering - Optimized design for quiet operation and helps resist wear, salt, road grime and oil.Plug and play - pre-installed ball joints and sealing sleeves, can be used without maintenance.LONG LIFE - The

Contact Now

Exemplary Precision: Meticulously engineered by a professional OEM to meet strict OEM specifications and undergo rigorous quality control testing, ensuring unparalleled quality and reliable operation.Superior Functionality: With a corrosion-resistant coating for exceptional longevity and greased ball joints to simplify maintenance, these control arms offer unmatched performance.Effortless Compatibility: Designed with a simple and lightweight construction to adapt to various applications, these control arms meet or even exceed OE standards in form, fit, and function.Seamless Replacement: Enjoy

Contact Now

Unparalleled Excellence: Crafted by a professional OEM to adhere to strict OEM specifications and pass rigorous quality control standards, these control arms are guaranteed to deliver outstanding quality and reliable performance.Optimal Performance: Featuring a corrosion-resistant coating for extended lifespan and greased ball joints for effortless maintenance, these control arms offer superior functionality.Effortless Installation: With their simple and lightweight design, these control arms are tailored to meet diverse application needs while maintaining OE form, fit, and function.

Contact Now

Unparalleled Quality: Crafted by a skilled OEM according to stringent OEM specifications and rigorous quality control standards, each component undergoes 100% testing to ensure dependable performance. Unrivaled Performance: Boasting a corrosion-resistant coating for extended longevity and greased ball joints for hassle-free maintenance, these control arms offer superior functionality. Effortless Installation: With a simple and lightweight design tailored to fit diverse application needs, our new ball joint control arms come preinstalled for convenient and problem-free installation.&n

Contact Now

Customized Suspension: The Advantages of Adjustable Control Arm Designs"Certain control arms offer adjustable designs, allowing vehicle owners to customize adjustments based on their individual needs and driving style. This customization capability enables the suspension system to adapt better to different road conditions and driving demands, resulting in optimized performance and improved handling.Enhancing Vehicle Dynamics: The Role of Control Arms in Handling Performance"The design and adjustment of control arms play a vital role in enhancing overall vehicle dynamics.

Contact Now

Optimizing Suspension Response: How Control Arm Design Enhances Ride Comfort""Enhancing Handling Performance: The Impact of Control Arm Design on Vehicle Dynamics"The coping with overall performance of a car is noticeably influenced with the aid of the diagram and adjustment of its manipulate arm. The manage arm performs a critical position in supplying secure suspension guide and decreasing physique tilt and roll.

Contact Now

Improved Handling: The Influence of Swingarm Design on Vehicle Dynamics A vehicle's handling is greatly influenced by swingarm design and tuning. The swingarm plays a key role in providing stable suspension support and limiting body roll and body roll. By investing in quality control arms, riders can benefit from increased cornering stability and flexibility, which are critical to driving stability.

Contact Now

About this item【Premium Quality】Built to stringent OE specifications and strict quality control standards by the professional OEM manufacturer, 100% function tested for reliable performance【Better Performance】Corrosion-resistant coating for long-life performance, greased ball joints for easy maintenance, light-weight construction for application requirements, meet or exceed OE form, fit and function【Perfect Fit】Direct replacement for a proper fit, brand new control arms with ball joints are pre-assembled for a trouble-free installation【Amazing Price】Factory direct pricing with no middleman mar

Contact Now

Cost-effective:We are a manufacturing unit direct sales.Customers can spend a small quantity of cash and get excessive fine Control Arm and Ball Joint Assembly.COMPLETE ASSEMBLY:Brand new suspension manipulate Arm Ball Joint Assembly,All components are pre-assembled for a trouble-free installation.HEAVY DUTY CONSTRUCTION: Manufactured in ISO licensed facility,Made with excessive electricity metal tubing with stable plate mounting brackets for most appropriate power and durabi

Contact Now