This control arm is for Ford Mondeo 07 model, the oe number of this Ford Mondeo 07 control arm is:AFD020 this control arm is used for that part of this Ford Mondeo 07 model, main is Front Lower Rocker Arm R and Front Lower Rocker Arm L this control arm has Aluminum alloy materials and steel materials types.Jinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

This control arm is for Ford Edge model, the oe number of this Ford Edge control arm is:AFD020 this control arm is used for that part of this Ford Edge model, main is Front Lower Rocker Arm R and Front Lower Rocker Arm L this control arm has Aluminum alloy materials and steel materials types.Jinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

OE Quality - Manufactured in ISO9010 certified facility,Made with high strength steel tubing with solid plate mounting brackets for superior strength and durability.Each part is built to stringent OE specifications.Stable characteristics,High reliability.FEATURES - Each control arm assembly is designed for specific application,All parts are assembled in a fully automatic shop to hold the tightest engineering tolerance and to achieve the perfect OE fit.Rigorously tested for secure and sustained performance by team of skilled engineers.Including the application of specific heat treatment hardwar

Contact Now

Cost-effective:We are a factory direct sales.Customers can spend a small amount of money and get high quality Control Arm and Ball Joint Assembly.COMPLETE ASSEMBLY:Brand new suspension control Arm Ball Joint Assembly,All parts are pre-assembled for a trouble-free installation.HEAVY DUTY CONSTRUCTION: Manufactured in ISO certified facility,Made with high strength steel tubing with solid plate mounting brackets for superior strength and durability.PREMIUM QUALITY:At TUCAREST,We application engineer,design,manufacture and test all of our products to meet or exceed OEM equivalent parts in terms of

Contact Now

Jinan YIFUDE Electromechanical Equipment Co., Ltd. is located in the beautiful capital city of Shandong Province - Jinan - the City of Spring. YIFUDE founded in 2006, and the company successfully passedd the trademark registration of "YIFUDE" at the same year. After years of hardwork, YIFUDE has gradually developed into a new comprehensive modern enterprise integrating design, research and development, manufacturing and sales & services. JJinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

This control arm is for Ford Fiesta 09 model, the oe number of this Ford Fiesta 09 control arm is: DG8034350,DG8034300 . this control arm is used for that part of this Ford Fiesta 09 model, main is Front Lower Rocker Arm R and Front Lower Rocker Arm L this control arm has Aluminum alloy materials and steel materials types.oe numberproduct namecar modelDG8034350Front Lower Rocker Arm LFord Fiesta 09-DG8034300Front Lower Rocker Arm RFord Fiesta 09-Jinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

ABOUT US:YIFUDE provides many types of auto parts and accessories for our customer with the highest quality product and passionate customer service. Each product design is precision-engineered to strict tolerances based on a clear understanding of the original equipment part, original vehicle design and performance requirements. Use high standards components and each design is extensively tested for durability and performance.

Contact Now

This control arm is for Volkswagen control arm model, the oe number of this 1EA411315C, 1ED407365,Old Ford Mondeo 03-07 control arm this control arm is used for that part of this Volkswagen control arm model, main is Volkswagen control arm control Arm R and Front Lower Rocker Arm L this control arm has Aluminum alloy materials and steel materials types.Jinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

Superior Build Quality: These control arms are meticulously crafted by a professional OEM according to strict OEM specifications and subjected to rigorous quality control standards, ensuring exceptional quality and reliable performance.Unmatched Performance: Equipped with a corrosion-resistant coating for extended durability and greased ball joints for effortless maintenance, these control arms offer superior functionality.Seamless Compatibility: The simple and lightweight design of these control arms meets a wide range of application needs while surpassing OE standards in form, fit, and funct

Contact Now

Outstanding quality. Built by a professional OEM to strict OEM specifications and strict quality control standards, 100% tested for reliable operation. Superior performance. Corrosion resistant coating for long life, greased ball joints for maintenance.

Contact Now

YIFUDE Electromechanical Equipment Co., Ltd. is the largest supplier of auto parts in northern China. We have factories in Shandong and Hebei, Guangdong. We mainly make automotive chassis parts. We have a lot of stock, and we can give customers the best price and best quality.The role of the car stabilizer rod is to maintain the stability of the car and prevent the car from rolling too much.

Contact Now

About this item【Premium Quality】Built to stringent OE specifications and strict quality control standards by the professional OEM manufacturer, 100% function tested for reliable performance【Better Performance】Corrosion-resistant coating for long-life performance, greased ball joints for easy maintenance, light-weight construction for application requirements, meet or exceed OE form, fit and function【Perfect Fit】Direct replacement for a proper fit, brand new control arms with ball joints are pre-assembled for a trouble-free installation【Amazing Price】Factory direct pricing with no middleman mar

Contact Now

Premium Quality Built to stringent OE specifications and strict quality control standards by the professional OEM manufacturer, 100% function tested for reliable performanceBetter Performance Corrosion-resistant coating for long-life performance, greased ball joints for easy maintenance, light-weight construction for application requirements, meet or exceed OE form, fit and functionPerfect Fit Direct replacement for a proper fit, brand new control arms with ball joints are pre-assembled for a trouble-free installationAmazing Price Factory direct pricing with no middleman markup delivers except

Contact Now

This control arm is for Envision 15- model, the oe number of this Envision 15- control arm is: .84034525,84034526 this control arm is used for that part of this Envision 15-- model, main is Rear Rocker Arm L (Blade) and Rear Rocker Arm R (Blade)this control arm has Aluminum alloy materials and steel materials types.OEMproduct name car model84034525Rear Rocker Arm L (Blade)Envision 15-84034526Rear Rocker Arm R (Blade)Envision 15-As an auto parts company, our main products include automotive cont

Contact Now

OE/OEM Part Number:51360-SNA-903,51350-SNA-903,52371-SNA-A03,52370-SNA-A03。

Contact Now

Apply to ACURA CL 4 Cylinder 1997-1999 HONDA Accord Coupe 1998-1999 HONDA Accord Coupe V6 2002 HONDA Accord Sedan 1998-2002 HONDA Civic 2006-2011 HONDA Civic EX 2006-2011 HONDA Civic GX 2001 HONDA Civic Si 1999-2000 HONDA Civic Si 2002-2003 HONDA Insight 2010-2014.Standard Export Package: Plastic Bag Shrink + Neutral / Brand box + Carton Box + Pallet.The size of the product:Front width1:137.5 height1:52.2 Thickness:15.9

Contact Now

Superior stopping power: Our brake pads are engineered to provide consistent and reliable braking performance, even under extreme conditions.Long-lasting durability: Our brake pads are made from high-quality materials that are designed to last longer than traditional brake pads, reducing the need for costly brake replacements.Reduced brake dust: Our brake pads are designed to reduce brake dust, helping to maintain a clean and healthy driving environment.Easy installation: Our brake pads are easy to install and can be done in most cases without professional assistance.Competitive pricing: Our b

Contact Now

Prevent excessive lateral roll of the body when cornering. The purpose is to prevent the car from lateral tipping and improve ride comfort. The stabilizer bar is a torsion bar spring made of spring steel, shaped like a "U", and runs across the front and rear of the car.

Contact Now

This product 25798011 25798012 Front Lower Rocker Arm R Front Lower Rocker Arm L apply to Buick Enclave 09- car model.Our products are 100% tested.We supply all kinds of GM Buick parts, suspension parts, engine parts, chassis parts.Our car suspension arms are made of aluminum alloy and steel.

Contact Now

Buick GL8 control arm MOOG advanced control arms are suitable for various car brands at home and abroad, and their engineering design has structural strength and anti-corrosion performance.Carbon Fiber Bearings - Added strength through process hardened studs combined with a patent pending carbon fiber reinforced bearing which reduces sleeve friction and extends sleeve life compared to typical unreinforced bearings.High Precision Engineering - Optimized design for smooth operation and helps resist wear, salt, road grime and oil. Ready to install - pre-installed ball joint and sealing sleev

Contact Now

This control arm is for BMW X3 G08 18 control arm model, the oe number of this 32106871884, 32106871892, Old Ford Mondeo 03-07 control arm this control arm is used for that part of this BMW X3 G08 18 control arm model, main is BMW X3 G08 18 control arm R and Front Lower Rocker Arm L this control arm has Aluminum alloy materials and steel materials types.Jinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

This control arm is for NISSAN 54501-8H310 control arm model, the oe number of this 54501-8H3104, 54500-8H310 Old Ford Mondeo 03-07 control arm this control arm is used for that part of this BMW X3 G08 18 control arm model, main is NISSAN 54501-8H310 control arm R and Front Lower Rocker Arm L this control arm has Aluminum alloy materials and steel materials types.Jinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

This control arm is for RAV-4 06- Rear Curved control armmodel, the oe number of this 48790-0R010, 54500-8H310 Old Ford Mondeo 03-07 control arm this control arm is used for that part of this BMW X3 G08 18 control arm model, main is RAV-4 06- Rear Curved control arm R and Front Lower Rocker Arm L this control arm has Aluminum alloy materials and steel materials types.Jinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

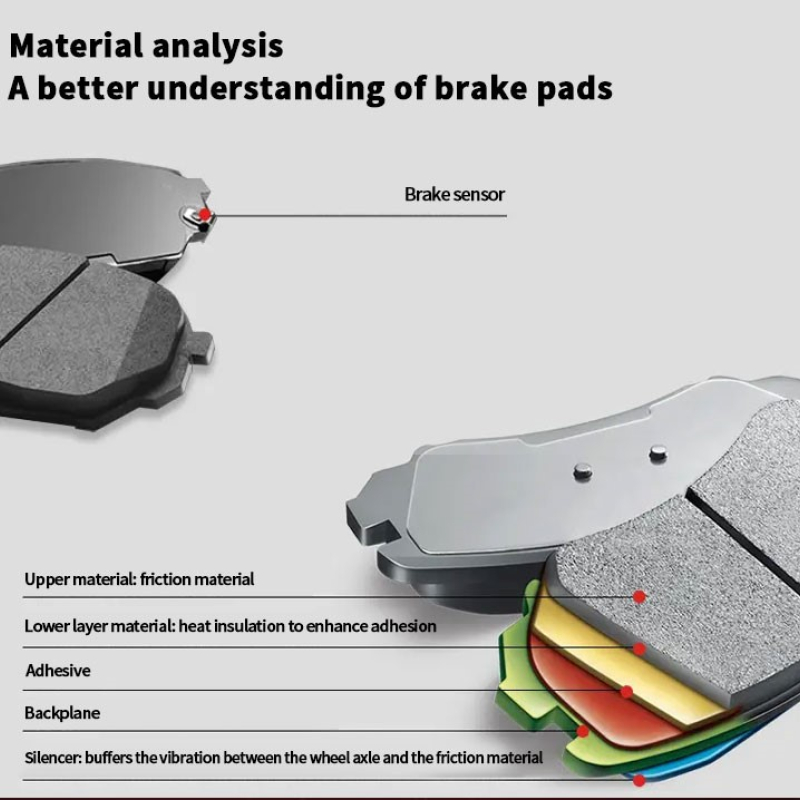

Our advantagesWe specialize in Korean chinese and Japanese auto parts and also have a few American auto parts1 Suspension parts: suspension bushing, Control arm, Ball joint, shock absorber, Shock strut2 Steering system: Bearings, Axle shaft, C.V joint, Power steering rack, Power steering pump Stabilizer link、Tie rod and Rack end, Steering knuckle3 Brake parts: BRAKE PADS, Brake Drum and disc, Brake shoe, Brake caliper, Brake cyliner, Brake booster, Brake adjuster4 Trasmission system: Tripod Joints, Clutch disc and cover, Clutch master cylinder, Universal jointsCenter bearing5 Eletric system: a

Contact Now