MOOG superior manage hands are appropriate for a variety of auto manufacturers at domestic and abroad, and their engineering diagram has structural energy and anti-corrosion performance.Carbon Fiber Bearings - Added power via technique hardened studs blended with a patent pending carbon fiber bolstered bearing which reduces sleeve friction and extends sleeve lifestyles in contrast to common unreinforced bearings.High Precision Engineering - Optimized sketch for clean operation and helps withstand wear, salt, street filth and oil.Ready to installation - pre-installed ball joint and sealing slee

Contact Now

The Ford Focus 12 Ball Joint is a part that connects the wheel assembly to the suspension system. It is responsible for allowing the wheel to rotate freely while maintaining its position relative to the vehicle's frame.The ball joint is typically made of a rubber-coated steel component that is connected to the suspension arm by a pivot point. The ball joint's ball socket is located at the top of the socket and is made of a high-quality steel that is resistant to wear and tear.

Contact Now

Vios 06 Model Ball Joint is a component used in automotive suspension systems, it is one of the most important parts of the suspension system. Ball Joint refers to a component that can turn, which is used to connect the wheel to the suspension system and enable the wheel to rotate. In Vios 06 Model, Ball Joint is one of the components that connect the front wheel and the suspension system.Ball Joints are one of the key components in the suspension system, they provide enough flexibility to keep the wheels smooth on uneven roads.

Contact Now

MOOG advanced control arms are suitable for various domestic and foreign automobile brands, and their engineering design ensures structural strength and anti-corrosion performance. Carbon Fiber Bearings: Added strength from hardened pins combined with a patent-pending reinforced carbon fiber bearing that reduces bushing friction and increases bushing life compared to typical non-reinforced bearings. Precision Engineering - Optimized design for smooth operation and resistance to wear, salt, road grime and oil. Ready to install – ball joint and sealing sle

Contact Now

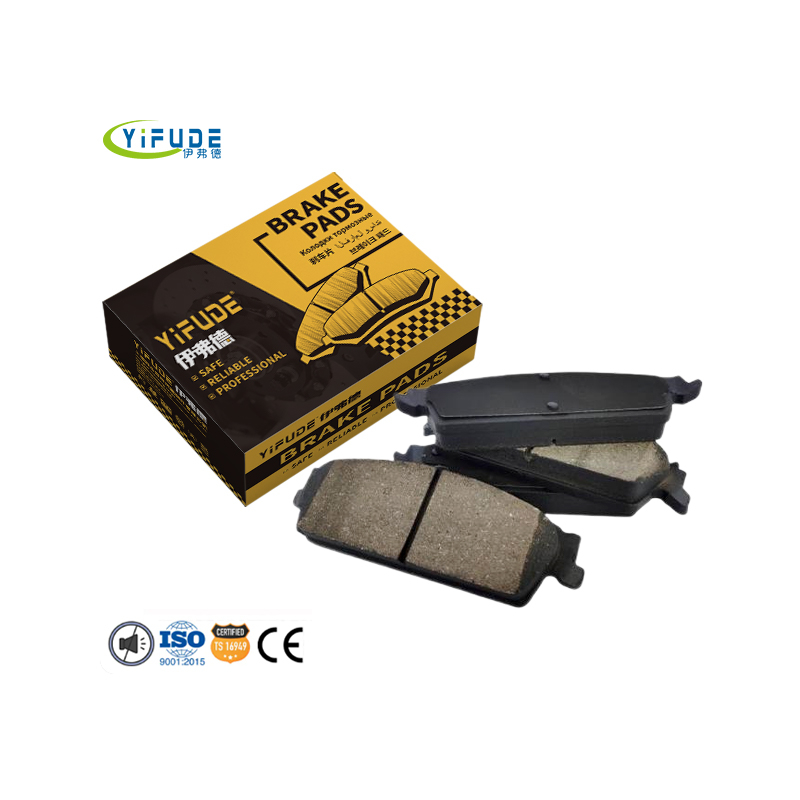

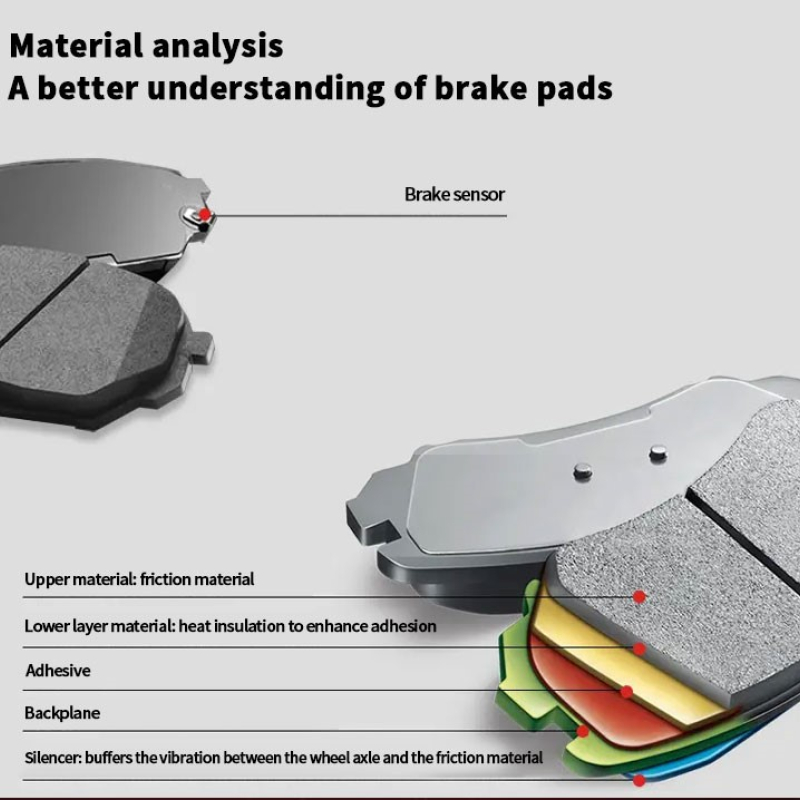

The brake pads on your Mercedes are responsible for slowing your vehicle down and bringing it to a safe stop. Every time you press the brake pedal, hydraulic fluid flows to each brake caliper clamping the brake pads to each side of the brake rotors. The clamping of the brake pad friction material creates drag between the pads and rotors, slowing each wheel. The harder the brake pedal is pushed, the harder the brake pads clamp the rotors and the faster the wheels slow to a stop.

Contact Now

Buick GL8 control arm MOOG advanced control arms are suitable for various car brands at home and abroad, and their engineering design has structural strength and anti-corrosion performance.Carbon Fiber Bearings - Added strength through process hardened studs combined with a patent pending carbon fiber reinforced bearing which reduces sleeve friction and extends sleeve life compared to typical unreinforced bearings.High Precision Engineering - Optimized design for smooth operation and helps resist wear, salt, road grime and oil. Ready to install - pre-installed ball joint and sealing sleev

Contact Now

Ford Mondeo 07 ball joint is a replacement part that connects the steering knuckle to the lower control arm of a car. The ball joint is a critical component of the suspension system, as it allows the wheel to rotate and make steering movements. The ball joint on the Ford Mondeo 07 is designed to withstand the forces and stresses of everyday driving, including steering and cornering.The ball joint is made from high-quality materials and features a ball-and-socket design that allows for a wide range of movement.

Contact Now

Our advantageWe have accessories for Korean cars, Japanese cars, Chinese cars, American cars, German cars,1 Suspension components: Suspension bushings, control arms, ball joints, valve covers, timing kits, hub bearings, ball joints.Strong and durableSafe and ReliableForged By Steel/AluminumExact Force Conduction.Reliable Replacement: This control arm and ball joint assembly serves as a trustworthy substitute, directly replacing the original assembly in specific vehicle applications.Efficient Repair: Each assembly comes complete with pre-installed ball joints and bushings, saving time and effor

Contact Now

This ball joint is suitable for Ford New Transit V362.oe numberproduct namecar modelRFD013Inner Ball Joint L/RNew Transit V362BFD014Outer Ball Joint L/RNew Transit V362LFD017Front Stabilizer Rod L/RNew Transit V362Jinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

Jinan YIFUDE Electromechanical Equipment Co., Ltd. is located in the beautiful capital city of Shandong Province - Jinan - the City of Spring. YIFUDE founded in 2006, and the company successfully passedd the trademark registration of "YIFUDE" at the same year. After years of hardwork, YIFUDE has gradually developed into a new comprehensive modern enterprise integrating design, research and development, manufacturing and sales & services. JJinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

Applicable to these models AUDI A4 1997AUDI A4 2000-2005 AUDI A4 Avant 1998AUDI A4 Quattro 1999AUDI A4 Quattro 2003-2004 AUDI A6 1999-2000AUDI A6 2002AUDI A6 Quattro 312mm Rotors 2000-2001 AUDI A8 Quattro 2001-2002AUDI Allroad Quattro 2001-2003 AUDI S4 2000-2002AUDI S8 2001-2003AUDI TT 2000-2005AUDI TT Quattro 2000-2005 PEUGEOT 405 1989VOLKSWAGEN Beetle 1998-2003VOLKSWAGEN Beetle 280mm Brake Rotors 2004-2005 VOLKSWAGEN Beetle 288mm Brake Rot

Contact Now

Superior stopping power: Our brake pads are engineered to provide consistent and reliable braking performance, even under extreme conditions.Long-lasting durability: Our brake pads are made from high-quality materials that are designed to last longer than traditional brake pads, reducing the need for costly brake replacements.Reduced brake dust: Our brake pads are designed to reduce brake dust, helping to maintain a clean and healthy driving environment.Easy installation: Our brake pads are easy to install and can be done in most cases without professional assistance.Competitive pricing: Our b

Contact Now

Buyer Notice - Please check the original equipment part numbers and the application for the replacement, buy the right one you needNo.GradeCar BrandCar ModelProduct NameExisting Assmbly CodeNew CodeQuantity /cartonYearOutput617CImported Audi Audi Q7 (4LB) Front Left Shock Absorber (With Buffer Spring)Audi Q7 (4LB) Front Left Shock Absorber (With Buffer Spring)946030462006.03-2015.083.0T,3.6L,4.2L,6.0L618CImported Audi Audi Q7 (4LB) Front Right Shock Absorber (With Buffer Spring)Audi Q7 (4LB) Front Right Shock Absorber (With Buffer Spring)9460303620

Contact Now

Disc Brake PadLet's face it, brakes pads palms down are the most necessary elements of our vehicle. Our brake pads enable us to quit our automobiles with a easy push of a brake pedal. Essentially brake pads convert the kinetic strength of the automobile to thermal electricity via friction.

Contact Now

Apply to ACURA CL 4 Cylinder 1997-1999 HONDA Accord Coupe 1998-1999 HONDA Accord Coupe V6 2002 HONDA Accord Sedan 1998-2002 HONDA Civic 2006-2011 HONDA Civic EX 2006-2011 HONDA Civic GX 2001 HONDA Civic Si 1999-2000 HONDA Civic Si 2002-2003 HONDA Insight 2010-2014.Standard Export Package: Plastic Bag Shrink + Neutral / Brand box + Carton Box + Pallet.The size of the product:Front width1:137.5 height1:52.2 Thickness:15.9

Contact Now

two kinds SEMI-METALLIC brake pads Formular code:YIFUDE110 Friction level:EE Life(KMS):40,000-70,000 Advantage: High quality semi-metallic ,contains 60% metal fiber,longest life in all semi-metallic ,suir for heavy truck or Van.

Contact Now

Jinan YIFUDE Electromechanical Equipment Co., Ltd. is located in the beautiful capital city of Shandong Province - Jinan - the City of Spring. YIFUDE founded in 2006, and the company successfully passedd the trademark registration of "YIFUDE" at the same year. After years of hardwork, YIFUDE has gradually developed into a new comprehensive modern enterprise integrating design, research and development, manufacturing and sales & services. JJinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

MOOG advanced control arms designed for foreign and domestic brands have structural strength and corrosion resistance.Carbon Fiber Bearings - Induction hardened studs for increased strength, combined with patent pending carbon fiber reinforced bearings, compared with non-reinforced bearings, reduces sleeve friction and prolongs sleeve life.High Precision Engineering - Optimized design ensures quiet operation and helps protect against wear, salt, road grime and oil.Ready to install - pre-assembled ball joint and sealing sleeve, no maintenance.Long Life - The ball pin shape guarantees fatigue li

Contact Now

Superior Build Quality: These control arms are meticulously crafted by a professional OEM according to strict OEM specifications and subjected to rigorous quality control standards, ensuring exceptional quality and reliable performance.Unmatched Performance: Equipped with a corrosion-resistant coating for extended durability and greased ball joints for effortless maintenance, these control arms offer superior functionality.Seamless Compatibility: The simple and lightweight design of these control arms meets a wide range of application needs while surpassing OE standards in form, fit, and funct

Contact Now

About this itemDurably designed - extra coatings provide long-lasting rust and corrosion resistance,product has vivid and stunning color, prevents growing older and falling off, and ensures safety.The ball joint is uniform and full, the substances are sufficient, thick, and stop deformation and fracture.Use extraordinary add-ons to make certain the excessive nice of the products.Our manipulate palms have huge applicability,meets the wishes of most&nbs

Contact Now

About this item【Premium Quality】Built to stringent OE specifications and strict quality control standards by the professional OEM manufacturer, 100% function tested for reliable performance【Better Performance】Corrosion-resistant coating for long-life performance, greased ball joints for easy maintenance, light-weight construction for application requirements, meet or exceed OE form, fit and function【Perfect Fit】Direct replacement for a proper fit, brand new control arms with ball joints are pre-assembled for a trouble-free installation【Amazing Price】Factory direct pricing with no middleman mar

Contact Now

Exemplary Precision: Meticulously engineered by a professional OEM to meet strict OEM specifications and undergo rigorous quality control testing, ensuring unparalleled quality and reliable operation.Superior Functionality: With a corrosion-resistant coating for exceptional longevity and greased ball joints to simplify maintenance, these control arms offer unmatched performance.Effortless Compatibility: Designed with a simple and lightweight construction to adapt to various applications, these control arms meet or even exceed OE standards in form, fit, and function.Seamless Replacement: Enjoy

Contact Now

This control arm is for Ford Mondeo 13- model, the oe number of this Ford Edge control arm this control arm is used for that part of this Ford Mondeo 13- model, main is Ford Mondeo 13- control Arm R and Front Lower Rocker Arm L this control arm has Aluminum alloy materials and steel materials types.Jinan YIFUDE Electromechanical Equipment Co., Ltd.

Contact Now

Outstanding quality. Built by a professional OEM to strict OEM specifications and strict quality control standards, 100% tested for reliable operation. Superior performance. Corrosion resistant coating for long life, greased ball joints for maintenance.

Contact Now