Genuine Original bmw rear brake pads

1:300 employees, 70,000 ㎡ working space

2:OEM Supplier for PG405 ,GM and Chery and ODM Supplier

3: 2,800 Positive molds and 8 million sets brake pads annually.

4: 2,400 reference with ECE R90 certification,

5:Dyno and Krause test machine + 8 Technician Engineers

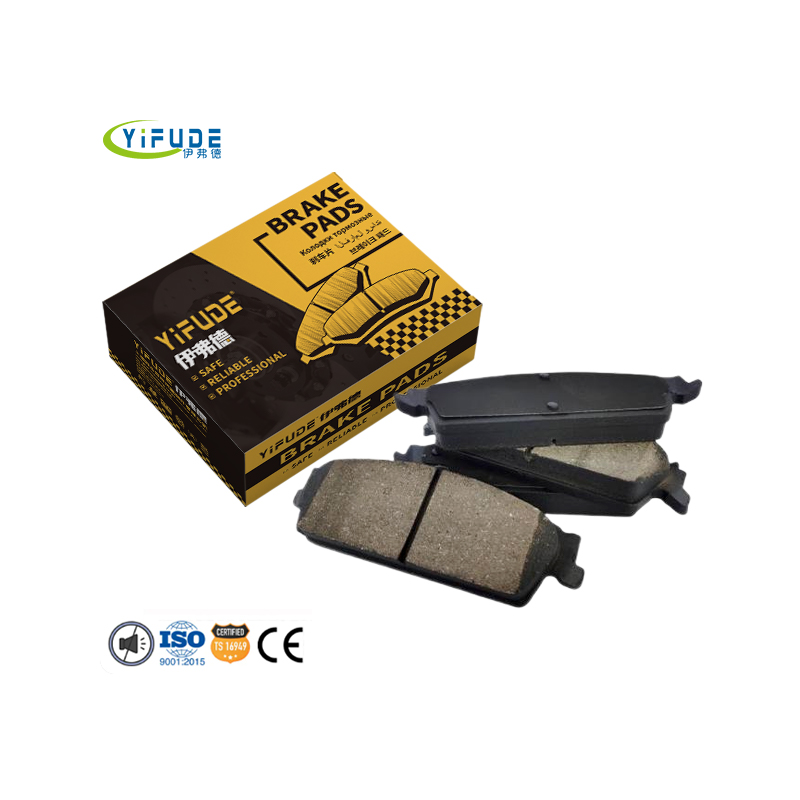

Disc Brake Pad

Let's face it, brakes pads hands down are the most important components of our vehicle. Our brake pads allow us to stop our vehicles with a simple push of a brake pedal. Unfortunately they don't last forever and are considered to be a major wear item which must be replaced before they completely wear out and damage the brake rotor costing you more in repairs. Brake pads can be made of several materials such as a semi-metallic compound, ceramic compound, or organic. Brake pads are suggested to be checked frequently during oil changes or routine services for wear to ensure you have at least the minimum pad thickness as stated by the car manufacturer.

Disc Brake Pad Failure Symptoms

Pulsating

Grinding

Squeeking

Rotor Glazing

Rotor Hot spots

A sizeable lip on the rotors outer edge.

Related News

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible